Industrial Division

In Hidramarín's Industrial Division we combine our knowledge with technical expertise to offer complete solutions to our customers.

Over the years, we have expanded our activity into various areas, including shipbuilding and ship repair, industrial maintenance and assembly, as well as the production of metal structures for the construction industry.

In addition, we have worked in a variety of sectors, both traditional sectors such as granite, wood and quarrying, as well as more innovative areas such as wind energy and the aeronautical industry.

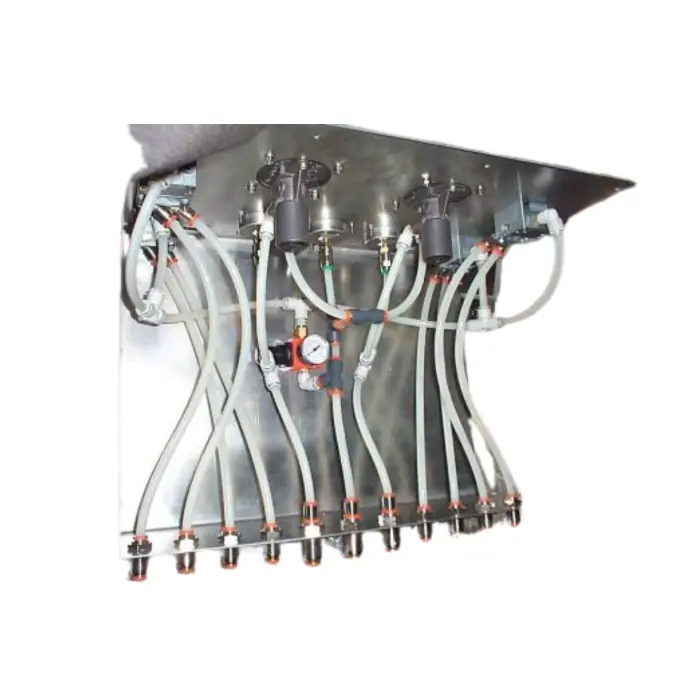

We manage materials for both new and retrofit installations:

- Hoses, fittings and rigid pipe.

- Hydraulic pumps, motors, control distributors, logic elements, etc.

- Tanks, bell couplings, pressure gauges and other accessories.

- Hydraulic, air and diesel filters.

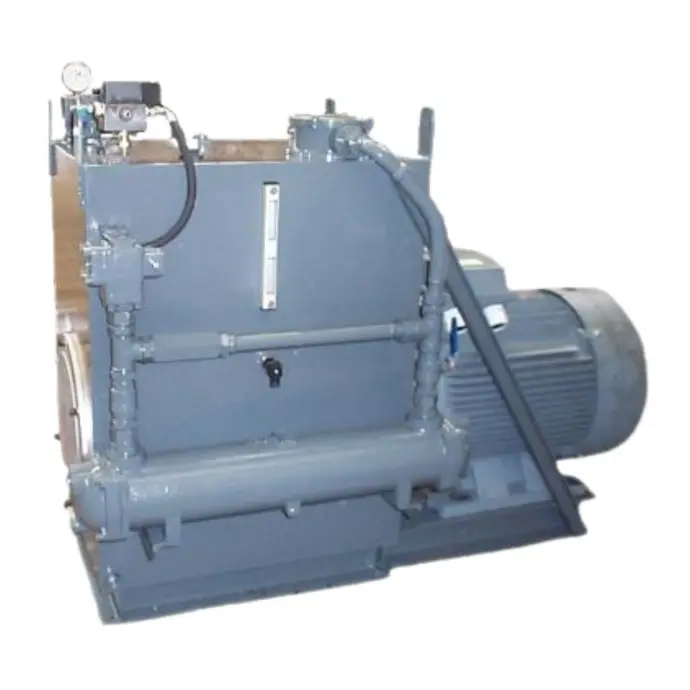

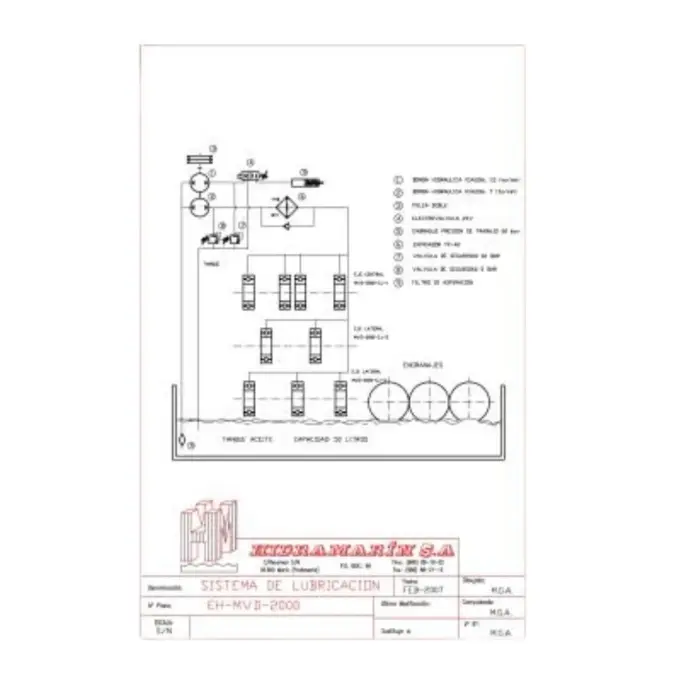

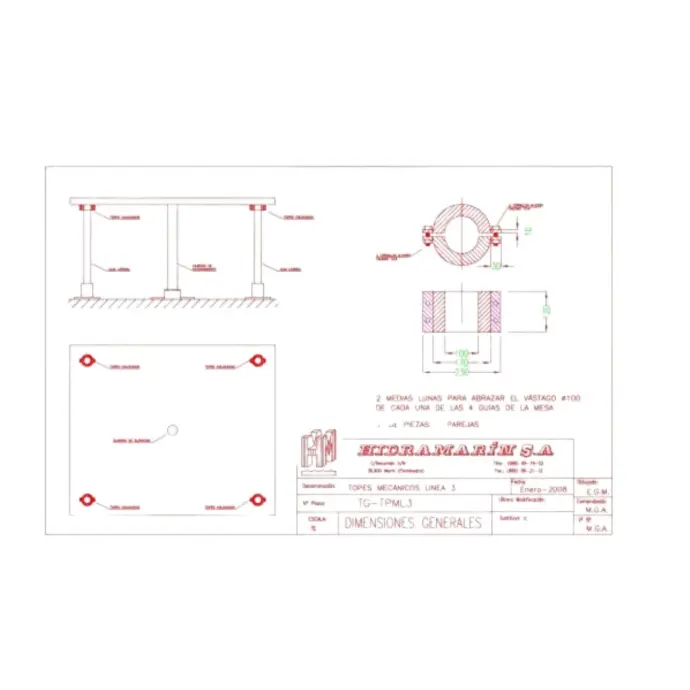

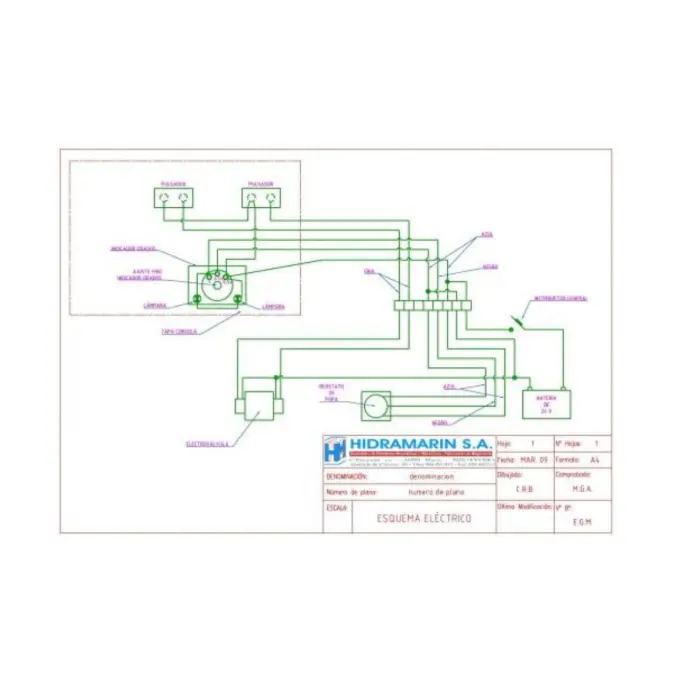

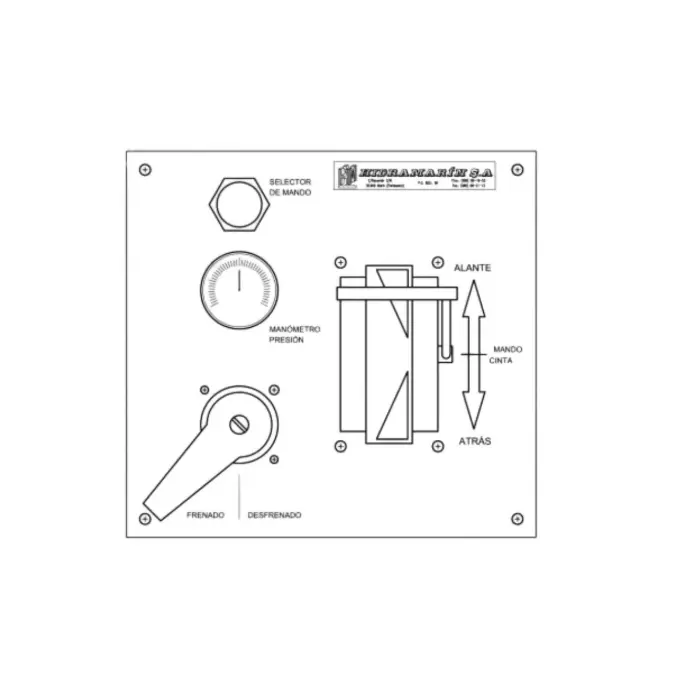

We manufacture all types of machinery, with fully customised development according to the needs of each client.

- Hydraulic power packs, pressure groups, filtration groups, etc.

- Chilgres, cylinders, power take-offs, conveyor belts, tables, etc.

- Winches, cranes, pallet turners, etc.

Analysis of the production process in search of greater efficiency:

- Management and reduction of takt times.

- Extension and/or modification of lines.

- Optimisation of the means of production.

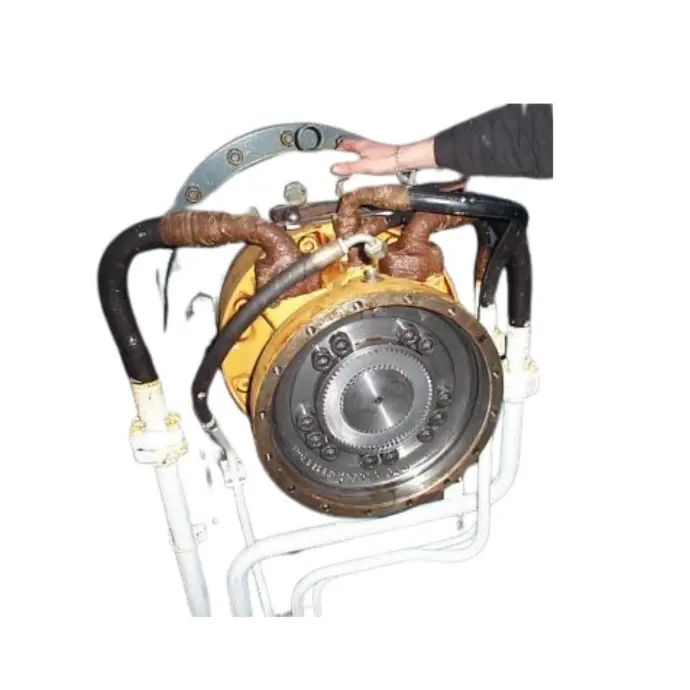

We carry out all types of industrial maintenance, providing our clients with highly qualified technical personnel and resources, such as filtering equipment, particle meters, digital diagnostic equipment and test benches. Our work focuses on three main areas:

- Corrective, preventive and predictive maintenance.

- Repair and testing of all types of hydraulic elements.

- Installation of hydraulic and pneumatic piping.

Our work consists of carrying out a technical audit, which will allow us to assess the resources being allocated to maintenance and draw up a strategic plan to optimise them. Main objectives:

- Improve the efficiency of maintenance personnel, seeking a balance between preventive and corrective maintenance to optimise the availability of production equipment.

- To guarantee the reliability of the installations to the maximum extent possible.

- Maximise the useful life of the production means.

- Establish a programme for the unification of references with the corresponding reduction in inventory levels.